The serialization machine ONELITE ONE-TRACE incorporates Inkjet thermal transfer printer (, capable of printing alphanumeric digits as well as linear and 2D barcodes like GS1 DataMatrix mainly for pharmaceutical application.

The artificial vision system performs the verification of printed data by quick images captures, using lenses with vision tools for 2D and OCR (Optical Character Recognition) / OCV (Optical Character Verification) codes, and integrated led lighting. It is also possible to carry out safety verification by crossing obtained data between readable texts and 2D codes to ensure data integrity.

The equipment has a main conveyor and an upper stabilization belt, both in perfect synchronization and powered by stepper motors, adjustable for a wide variety of carton sizes, assuring a proper movement of the product, free of vibrations in a broad range of speeds.

The ejection system removes any unreadable or incorrectly printed code to a rejection drawer, verified the correct entry with an input sensor.

All system of ONELITE ONE-TRACE are powered by steppers motors, commanded by high-resolution drivers allowing a perfect synchronization.

The ONELITE VISION traceability system allows to process batches of medicinal products creating unambiguous codes, according to GS1 standard recommendations, for each unit. At the same time, the system creates a database of easy viewing, with restricted access depending of user level according the security required for that information, in conformity with CFR 21 part 11 (FDA).

Enclosure structure manufactured with high transparency polycarbonate allows visualizing the work area and guarantee the machinery operator safety. Security system stop equipment immediately when the cabin is opened during machine operation.

PhC Cosmetics / Pharma Line: ONE-TRACE

Serialization Module for drugs traceability ONE-TRACE

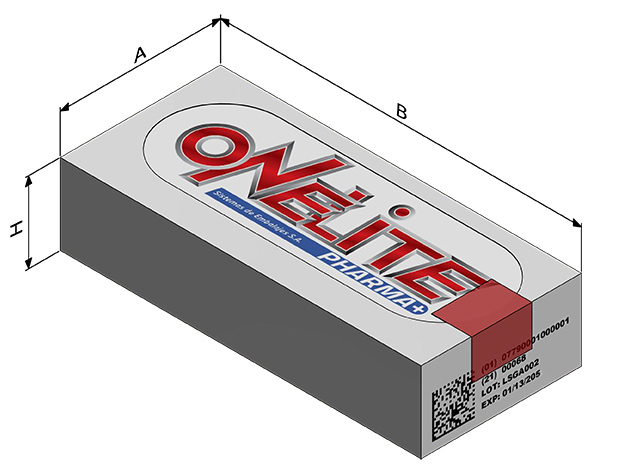

Electromechanic equipment designed to serialize carton cases in compliance with traceability requirements of pharmaceutical products.

Details Gallery

19-inch touch panel PC

Automatic boxes separator

AIRLESS boxes ejector

Main Features

- Main structure manufactured in stainless steel and anodized aluminum.

- Main conveyor and Upper stabilization belt synchronized, ensuring precision in the transport of the cases.

- Electromechanic ejection system (AIRLESS) with rejection drawer. Optional.

- Panel PC (HMI) 19 inches touchscreen.

- Enclosure structure manufactured with high transparency polycarbonate allows visualizing the work area.

- Security system that stop equipment immediately when the cabin is opened during machine operation.

- Display and download of production reports.

- Connection ports USB, ETHERNET.

- Fast machine setup and startup for a wide variety of carton sizes.

- Inalterable Event log (Audit Trail).

- Quality control of computerized system according to guidelines given by GAMP5 (ISPE) and 21 CFR Part 11 (FDA).

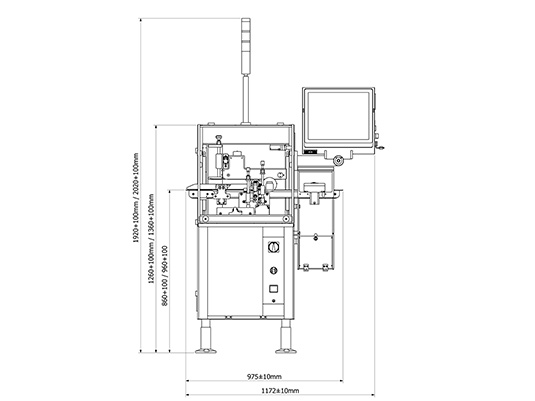

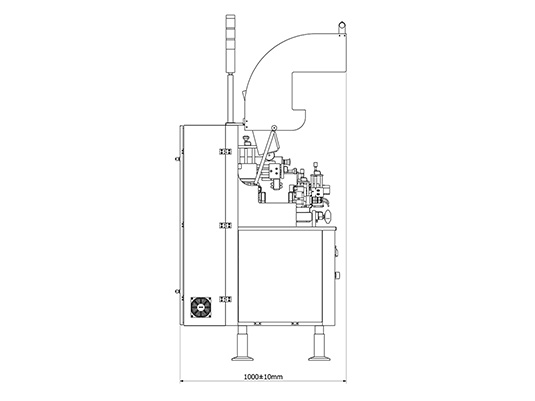

Actual Dimensions

Front Layout

Side Layout

Technical Data

| Dimensions (mm) - Lenght x Width x Height | 1172 x 1000 x 2120 |

| Working Height (mm) - Without / With extenders | 860-960 / 960-1060 |

| Weight (kg)/(Lb) | 250 / 551 |

| Installed Power (KVA) | 0,25 |

| Noise level (dB (A)) | 50 - 70 |

| Production Capacity (cases / minute) * | 200 |

| Speed range (meters/minute) * | 10 - 40 |

| Admisible cases (mm) - Lenght (B) x Height (H) x Width (A) | 55-190 x 15-100 x 30-170 |

| Printing Area (mm) - Height | 12,7 |

| Printer | Thermal Inkjet (TIJ) |

| Camera | High Resolution |

| * Depending on the acquired version of the ONE-TRACE, the production can reach 200 units/minute maximum, for cartons which width is equal or lower than 80 mm. For wider cartons, maximum production may be affected. | |

The mentioned characteristics can be modified without prior notice if the Company considers it for manufacturing or operating reasons. Operation voltages can be adaptable to each country or working environment.

Aware of the need to maximize space in the clean rooms in pharmaceutical industry, the size of our machines is one of the main premises at the time of the design of our entire Pharma Line.

GET IN TOUCH! Take advantage of the knowledge of our Sales Team by calling us today on +54 260 442 1956 or from here . We will be happy to help you to come up with the most effective solution for your requirements.