Controlled by a PANEL PC with 10.1” TFT color touchscreen that offers a friendly management for the operator. It has different available user account levels and a complete record of events to meet the standard 21 CFR Part 11 (FDA). The machine has also a USB port for downloading the Event´s log and for updating the software.

The settings for the different products can be easily saved by creating a program, which can be recalled at the time of tagging the same product again. Through the bottle separator parameter, it is possible to modify the operating speed, maintaining the synchronism of the entire machine.

In addition, the equipment features an electromechanical ejection system (AIRLESS), which is capable of removing from the line any bottle with defective codes or faulty labels to the reject box, where its entrance is detected by the input sensor.

Besides the LR-4000 requires minimum setup and maintenance.

PhC ABQ Cosmetics / Pharma Line: LR-4000

Labeling machine for bottles or vials LR-4000

Thanks to the ONELITE software, centering the label and changing the format in this machine is made easily and with minimal regulations. It can incorporate up to 2 labeling heads with transparent label detectors and automatic missing-label recovery.

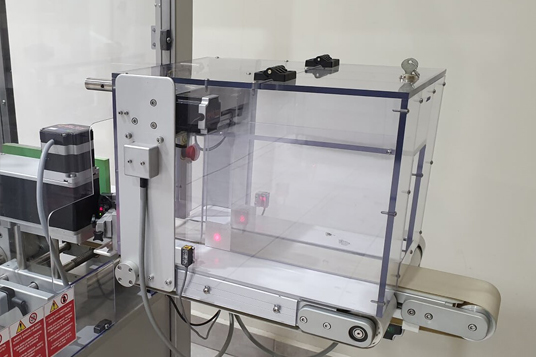

Details Gallery

Container separator with synchronized speed adjustment.

Discard system of rejected products with verification of entry into the drawer.

Mechanical regulation to easily adapt to different sizes of products.

Stepper motors that allow greater precision in the positioning of the parts.

Printed data verification system and / or label verification (Optional).

PANEL PC with 10.1” TFT color touchscreen

Outstanding Features

- Minimum space required.

- Speed adjustment allowing simple and fast variation on the production capacity according to the custom requirements.

- Appropriate Security Systems when the machine is operating, preserving the safety of the operator and the working environment.

- Rejection of products with defective label and detection their entrance into the reject box.

- Quality control by computerized system according to guidelines given by GAMP5 (ISPE) and 21 CFR Part 11 (FDA).

Optionals to be incorporate

For integration with e-Pedigree and serialization systems, the LR-4000 can be complemented with printers and data capture systems for traceability information, as the Codification and verification ONELITE system.

The encoding process is performed with the interaction between labeling and vision equipment where the information on the label to be dispensed it is checked before the product is labeled.

The artificial vision system ONELITE checks if the information printed on the label is correct and if it corresponds to the given product.

When the equipment is provided with Codification and verification system, it can work in different operating modes according to the custom requirements.

- Conveyor. The machine work only as conveyor of products.

- Labeling, without codification and without label verification.

- Labeling, with codification but without label verification.

- Labeling with codification and label verification.

This system allows you to make codification, serialization, printing, and verification for trazabilidad information providing an integral solution to the actuals pharmaceutical industry requirements.

It includes a thermal transference printer TTO or TIJ printer for 2D datamatrix and humanly readable text. According to the GS1 recommendations.

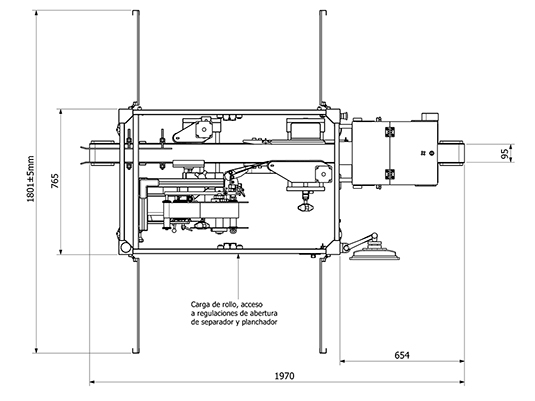

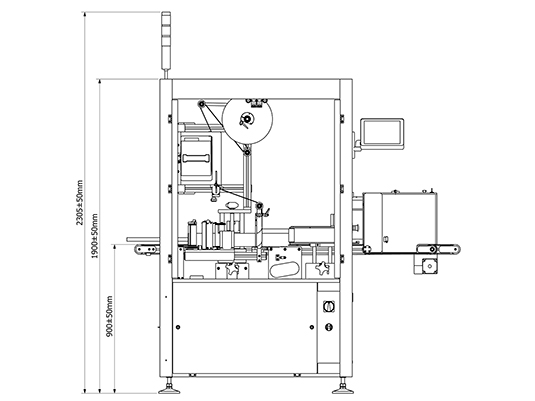

Actual Dimensions

Upper Layout

Front Layout

Technical Data

| Dimensions (mm) - Lenght x Width x Height | 1970 x 765 x 2300 |

| Weight (kg) | 385 |

| Installed Power(KVA) | 2 |

| Noise level (dB (A)) | ≤ 80 |

| Production Capacity (cases / hour) * | 4,000 - 9,000 |

| Speed range (metres/minute) * | 8 (Fix) |

| Admisible cases (mm) - Diameter x Height | 22-70 x 65-160 |

| Admisible labels (mm) - Height x Width | 15-230 x 20-75 |

| Printer | Thermal Transfer Overprinting (TTO). Thermal Inkjet (TIJ) (Opcional) |

| Camera | high resolution |

| * Depending on the bottle diameter. For the minimal allowable diameter 9.000 bottles /minute can be reached and for the maximal allowable diameter 4.000 bottles/minute can be reached. | |