This machine identifies and groups individual case codes of a pack into a new code that is subsequently printed and stuck on the pack. The AR-BASIC T-AP is provided with a high-resolution camera able to read 2D codes (DataMatrix) on the cases included in the pack. The ONELITE vision system assigns a unique serial number for each pack, relating this number with serials given to individual cases.

The AR-BASIC T-AP has a VideoJet DataFlex® 6230 printhead, offering a wide and flexible range of printing in packages as necessary. Once the label has been printed and applied, its information and the legibility are verified.

If the label is detected as nonconformity, the pack is automatically removed from the line to a discards drawer, endowed with a sensor that corroborates the effective entering of the pack.

In the process, a database containing all the codes (processed, accepted and rejected) is created, in order to ensure the tracking of the products, bringing security and integrity to the information during aggregation. It also allows to store parameter settings in programs, to be easily recovered later, when a new lot of the same product has to be processed.

The AR-BASIC T-AP requires minimal space for emplacement and installation, allowing easy operation thanks to a 15-inch touch screen, coordinating all the processes (image capture, printing, labeling, verification and rejection); storing information related to the whole process of production.

PhC Cosmetics / Pharma Line: AR-BASIC T-AP

Packs aggregation module AR-BASIC T-AP

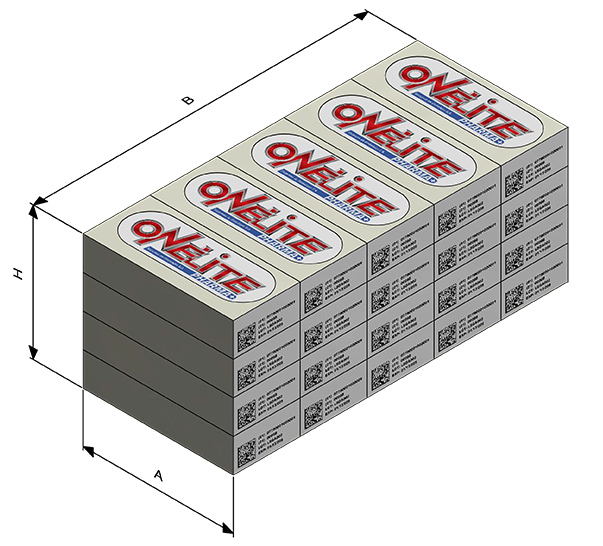

Equipment suitable for identifying and aggregate the code of all individual cartons inside a bundle to a new code recently printed on a label which will be placed on the bundle.

Outstanding Features

- Complete coordination between printer, camera and ejection control.

- Simple adjustment and setup (mechanical and digital parameters)

- Quality control of computerized system according to guidelines given by GAMP5 (ISPE) and 21 CFR Part 11 (FDA).

- Thermal transfer printing for 1D, 2D codes and human legible text.

- Redundant safety expulsion by product detection in the rejection drawer.

- Generation/import of serial numbers for processing in the equipment.

- Visualization and downloading of detailed production reports.

- Minimum space required.

- Generation/restoration and download of system backups.

Actual Dimensions

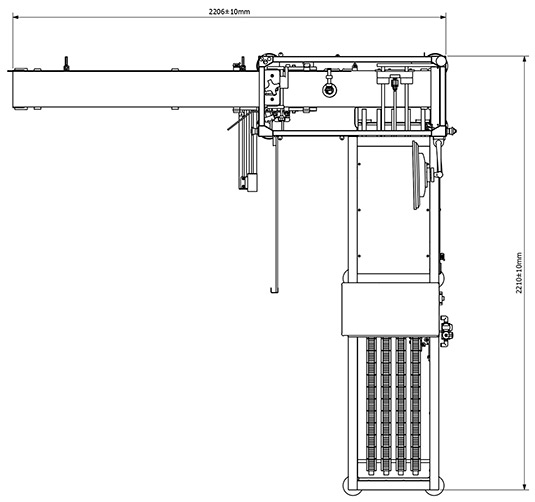

Upper Layout

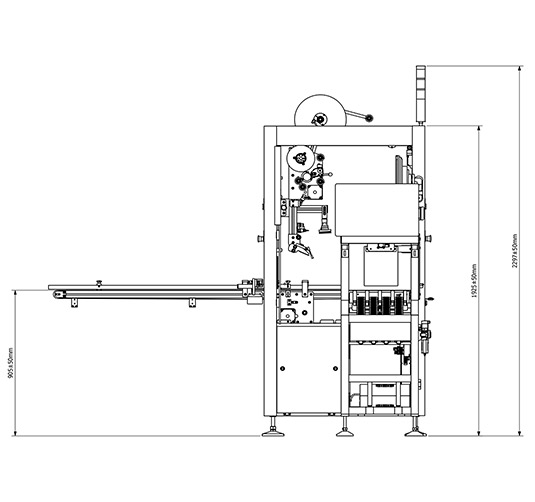

Front Layout

Technical Data

| Dimensions (mm) - Lenght x Width x Height | 2206 x 2210 x 2280 |

| Weight (kg) | 350 |

| Installed Power (KVA) | 1 |

| Air Pressure (bar) | 6 |

| Noise Level (dB (A)) | ≤ 80 |

| Production Capacity (packs / minute) * | 10 |

| Admisible packs (mm) - Lenght (B) x Height (H) x Width (A) | 100-330 x 70-195 x 80-200 |

| Admisible labels (mm) - Height x Width | 80 max. x 240 |

| Printer | Thermal Transfer Overprinting (TTO). (Op.) |

| * Depending on the acquired version of the AR-BASIC AP, the production will reach 17 packs/minute maximum, independently of the length, insofar as it does not surpasses 250mm. | |

The mentioned characteristics can be modified without prior notice if the Company considers it for manufacturing or operating reasons. Operation voltages can be adaptable to each country or working environment.

Aware of the need to maximize space in the clean rooms in pharmaceutical industry, the size of our machines is one of the main premises at the time of the design of our entire Pharma Line.

GET IN TOUCH! Take advantage of the knowledge of our Sales Team by calling us today on +54 260 442 1956 or from here . We will be happy to help you to come up with the most effective solution for your requirements.